SYNTHETIC MATERIAL

REHABILITATION - YES WE SCAN!

Shafts are permanently susceptible to corrosion. Aggressive media not only destroy the sewage channel area, but also attack rising shaft components such as rings and cones.

PREDL works with different remediation methods depending on the local conditions:

- Renovation with PREDL-GFK-components

- Renovation with CORPROTECT-lining

- Restoration with PREDL-FLEXLINER

- Restoration with PREDL-FRP PANEL

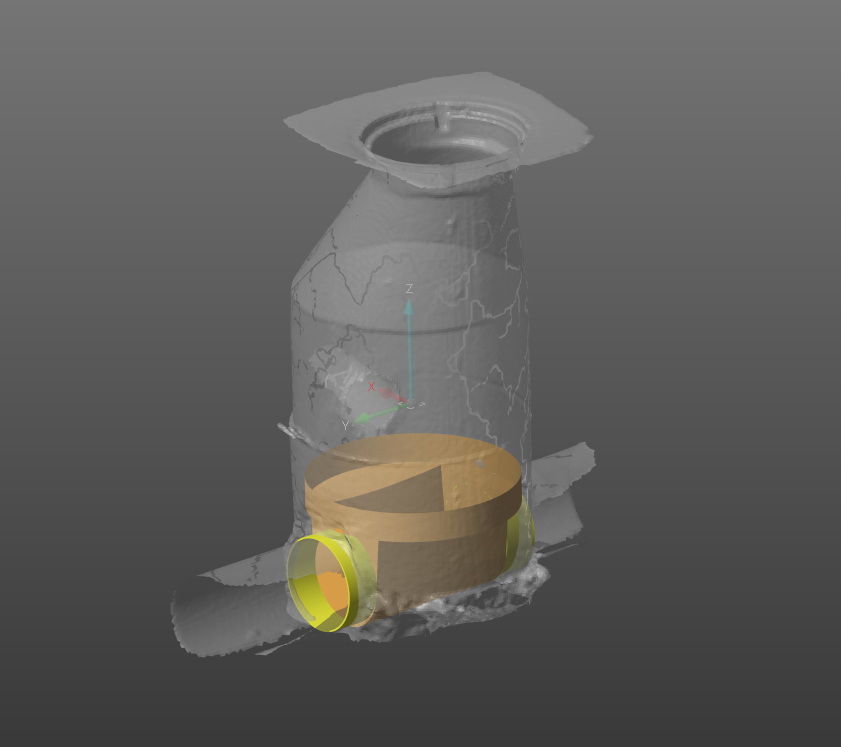

With SCAN-lining, PREDL offers on-site laser-based surveying as a service. The most modern laser technology enables precise recording of shaft data.

product Folder

Please find more detailed information in our product folder:

REHABILTATION PROCEDURES

MANHOLE-IN-MANHOLE SYSTEM

Manhole-in-manhole rehabilitation system with GRP rehabilitation base-liner + GRP pipe.

WITH CORPROTECT-LINING

Rehabilitation with PP CORPROTECT –lining (through the conus / coverslab access hole)

PREDL FLEXLINER SYSTEM

Rehabilitation with FLEXLINER base-liner + CORPROTECT-lining

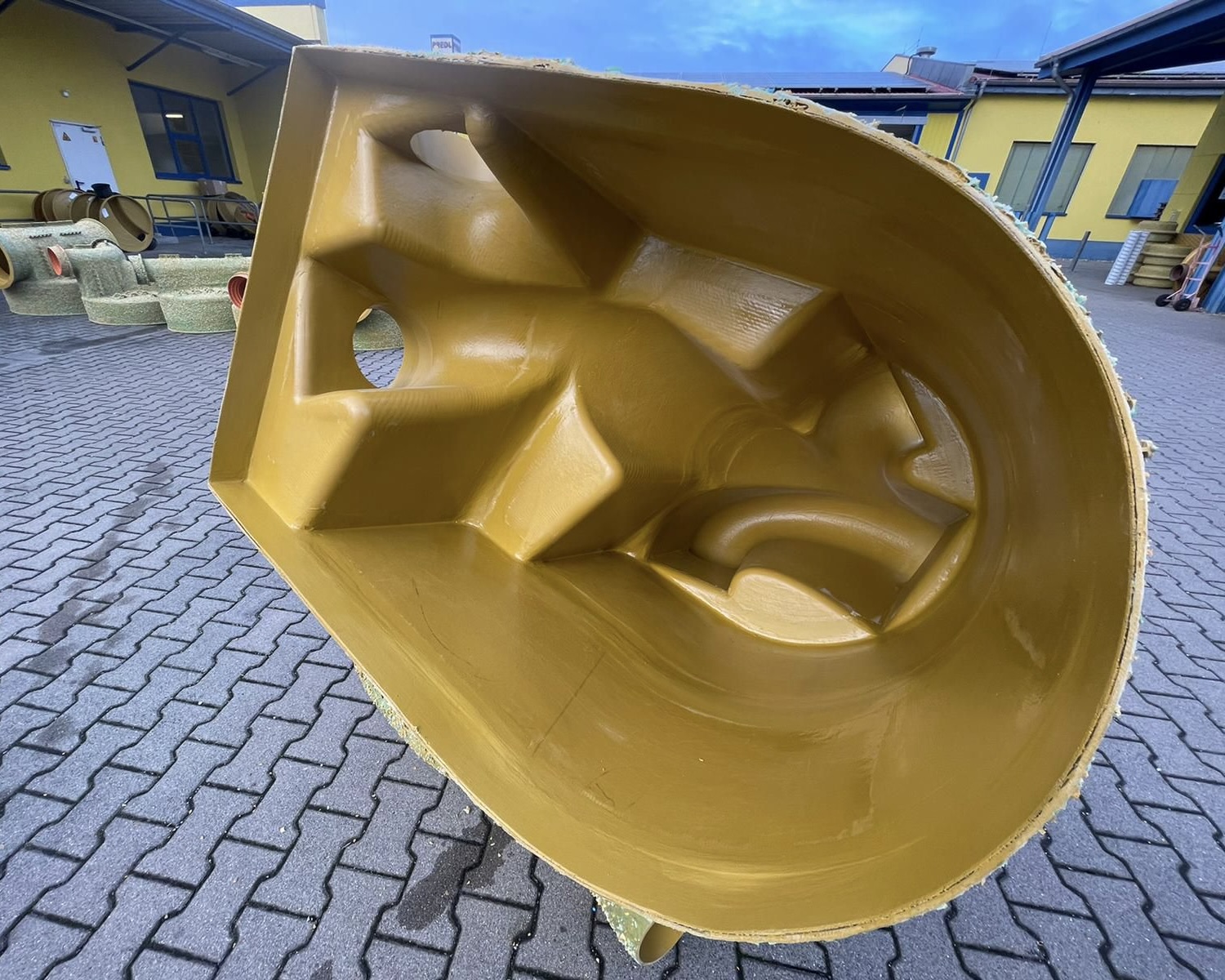

PREDL - FRP Panel

Customized renovation with FRP panels, tailored to each specific situation.

Manhole in Manhole Rehabilitation

The PREDL manhole-in-manhole rehabilitation process with a PREDL manhole base offers an innovative solution for severely deteriorated and damaged sewage manholes.

The process utilizes a fiberglass-reinforced plastic (FRP) pipe for the vertical extension of the rehabilitation of the manhole structure. This high-quality material choice ensures long-term durability and resistance to chemical and environmental influences.

Through the digitization of the existing manhole, changes and adjustments can also be made to meet current requirements.

Flexliner & CORPROTECT Lining

With the PREDL-FLEXLINER, trenchless manhole rehabilitation is possible within a very short time frame.

The FLEXLINER is installed undivided and without destruction; it is folded and inserted into the manhole through the cone. Inside the manhole, the new base is unfolded, aligned, and filled with high-quality mortar. The subsequent vertical lining can then be carried out using Corprotect.

PREDL FRP Panels

The rehabilitation process using PREDL FRP panels is particularly suitable for wastewater structures with unconventional geometries and high performance requirements.

The panels, custom-designed and manufactured by PREDL, stand out for their resilience against deformation, convenient transportability, and ability to provide enduring protection against corrosion.